Circular REE Supply for Europe

Recycling Magnets from End‑of‑Life Wind Turbines

>95%

Recovery>99%

Purity−68%

Cost vs mining−80%

Energy2025→2026

ProjectNd • Pr • Dy

OutputsWhy ReMag

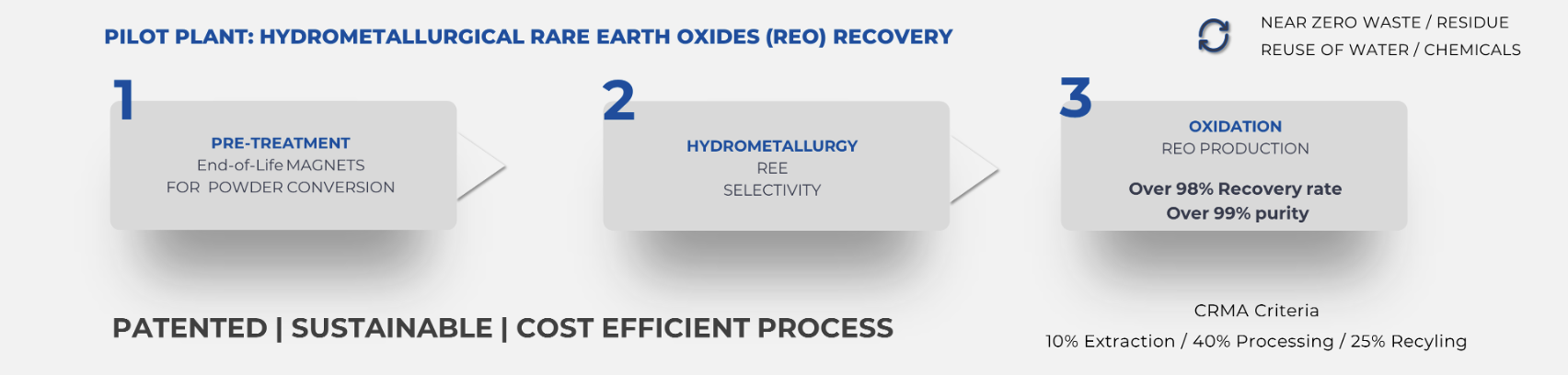

Europe recycles less than 1% of rare earths while supply is concentrated abroad. ReMag unlocks a domestic, traceable REE stream by transforming end‑of‑life magnets from wind and EVs into high‑purity oxides.

CRMA

Aligned with 2028 full application

Circular Societies

EIT RM Lighthouse

Responsible Sourcing

Traceable EU origin

Scale

Path to 15,000 t/y plant

Why it matters

Strategic Autonomy

Cuts import dependence by building EU‑based supply for rare earth magnets.

Climate & Industry

Feeds wind, EVs, and advanced electronics without new mining footprints.

Economic Value

Turns EoL magnets into bankable oxides and circular revenue streams.

- Magnets ≈ 90% of REE market value

- Validated recovery & purity targets

Impact

Environmental

- ~80% lower energy vs pyrometallurgy

- Closed‑loop water and reagent reuse

- LCA‑driven decisions and hotspot analysis

Economic

- −68% processing cost vs mining

- Pathway to €285M revenues post‑scale

- EU value captured in circular chain

Societal

- 100+ new jobs at commercialization

- PhD/MSc tracks, summer schools

- RIS impact in Portugal & Greece

Project Timeline

2025

Pre‑site validation, flowsheet, engineering freeze.

Pre‑site validation, flowsheet, engineering freeze.

2026

Pilot commissioning, optimization, scale‑up study for 10 kt/y.

Pilot commissioning, optimization, scale‑up study for 10 kt/y.

2027→

Industrialization pathway toward 15,000 t/y plant.

Industrialization pathway toward 15,000 t/y plant.

Contact & Coordination Team

For partnerships, pilot participation or press, contact the ReMag coordination team.

N9VE (Coordinator)